Roberto Gomez Barron, Engr ’25 (MS), came to Johns Hopkins Engineering for Professionals after years in aerospace design and manufacturing. He began his professional career in experimental test article designs for the Learjet 85; moved into tooling design for the Global 7500; consulted on production systems development projects for OEMs such as Dassault Falcon Jet, Airbus, and Bombardier; and later served as a new product introduction lead at Pratt & Whitney. In this role, he coordinated cross-functional teams to transition engine components from concept to production. These experiences pushed him to think beyond parts toward whole systems, setting the stage for graduate study in systems engineering. He currently works as a tooling engineering in the production systems department at Wisk.

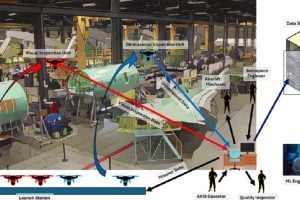

For his systems engineering capstone course, Gomez Barron designed an autonomous aerostructures inspection system capable of navigating production facilities and conducting real-time visual and dimensional inspections. “The goal was to reduce the risk of manufacturing defects while improving efficiency,” Gomez Barron says. “The idea was to use computer vision to detect surface damage, foreign object debris, or incorrectly installed components—and then improve that detection over time with a continuous learning framework.” In practice, that framework retrains the machine learning (ML) models with new inspection data and human feedback, so detection accuracy improves as the system operates. The system then produces inspection reports that integrate with existing quality processes to improve traceability and consistency.

Gomez Barron used a structured systems engineering approach that included stakeholder interviews and needs analysis; concept of operations and use cases; a functional architecture iterated into a feasible physical architecture; and a test and evaluation plan tied back to requirements. He combined trade studies, risk management, and project planning to inform his decisions—an approach he learned in his classes.

“One of the biggest technical challenges was designing the ML subsystem’s functional architecture and ensuring it could integrate smoothly with the broader system,” he says. “Balancing real-time data processing, modularity, and scalability was no small task.” Technology choices had to match current ML/computer-vision capabilities with operational constraints while preserving modularity and pathways for continuous model updates.

Gomez Barron says one of EP’s strengths is that faculty connect classroom concepts to industry practices, noting that skills he learned, such as system design and integration, and the ability to assemble complex components into a cohesive architecture, which he has implemented into Wisk’s organization’s workflows.

After completing his capstone, Gomez Barron says Wisk began drawing upon his new expertise. “I was asked to begin integrating systems engineering practices into our workflows,” he said. “And I was brought in to support the development of the autonomy system for a passenger UAS project—something that wouldn’t have happened without the experience I gained in the program.” Now working at the cutting edge of aerospace innovation, Gomez Barron credits EP with equipping him to lead across both physical and software domains.